User:Herna327/sandbox

Article Evaluation - Pasteurization

Although everything in the article is relevant to the topic, some sentences and their wording were distracting upon reading the article. Additionally, some of the points throughout were random (but still somewhat relevant) to the article. The article was written in a neutral tone, but I felt like some view points were overrepresented (alcoholic beverages section) while others were underrepresented (microwave volumetric heating section). The main topics of the article were the history and process of pasteurization, with the main focus being milk. Personally, I would have liked to see the article extended in terms of the "Products that are commonly pasteurized" section and further exploring the conditions and reasons as to why those products (beer, canned food, dairy products, eggs, milk, juices...) are pasteurized.

All of the citations I reviewed were working and supported the claims. Two of the 64 references used had "help" error yet I was still able to navigate to the sites with the hyperlink provided. Multiple of the references were obtained from government and education websites such as USDA, CDC, HHS, and Michigan State University, while many others were from journal articles published in journals such as Journal of Food Protection, Journal of Dairy Science, and British Dairy Journal - to mention a few. There were several books cited, which are reliable and non-biased sources, which are adequately used throughout. However, some of the references were not properly cited (three that I came across [Source 10, 24, and 25]). Those three improperly cited references appeared to be of news articles, which could express biased opinions; however, I was unable to note whether or not there was bias in the WikiPedia article as I could not track down those sources given their vague description/improper citing. Although the information in the article was useful, there is additional information that could be added just by reading our class textbook (3rd edition), that would provide more in-depth information of pasteurization. Additionally, new articles/research could be added given the recent advances in technology (mainly in regards to validation of pasteurization). In the "Talk" page of the article there are a few conversations of what is being covered in the article (flash pasteurization and the article lacking basic information and focusing greatly on milk). The article is currently rated a B-class article and is also of interest in two WikiProjects. Overall, the article is a good, basic beginning to inform readers of pasteurization, but can improve in terms of depth and grammar.

Article(s) of interest:

- High Pressure Processing - the "Talks" page only discussed a potential merge between HPP and another article (high pressure food preservation) and how HPP foods are used in the UK. The foods section could be thoroughly expanded given the advantages of HPP and how it is now used world-wide. The article is useful but VERY basic and can be used to further educate readers given new HPP research and history since the 1990s.

- Pasteurization - can improve on the basic information as suggested in the "Talks" page. Although the article is focused on milk, it can be expanded as mentioned above in other products commonly pasteurized. The "specifics/parameters" of pasteurization and its respective equipment could be improved and better explained to readers.

- Hurdle Technology - only two section in entire article (hurdles and synergistic effects). Can further elaborate on many points to educate readers. Nothing has been previously discussed in the "Talks" page.

- Food Irradiation - article explores a wide variety of sections, but very basic and superficial information. Can also focus more on the foods commonly exposed to irradiation and the process of irradiation. Additionally, the article could improve on the three most common forms of irradiation (gamma, UV, and e- beam).

Self-Assigned Article: Food Irradiation. Plan on cleaning up the citations and incorporate more food products and effects throughout the article. Additionally, plan on organizing and updating the "Treatment" section, focusing on the process of irradiation. As mentioned above, will improve on the three most common forms of irradiation and and known advantages and disadvantages. The "History Timeline" located at the bottom of the article can also be improved in the sense that the bullet points can be eliminated and turned into sentences and paragraphs given the references on each bullet point and history of irradiation.

The following are several references that will be used to improve the article:

- Food Processing Technology Principles and Practice - Book by P.J. Fellows

- Irradiation for Quality Improvement, Microbial Safety and Phytosanitation of Fresh Produce - Book by Peter A. Follett and Rivka Barkai-Golan

- Food Irradiation Research and Technology - Book by Xuetong Fan and Christopher H. Sommers

- Irradiation of Food Commodities: Techniques, Applications, Detection, Legislation, Safety and Consumer Opinion - Book by Ioannis S. Arvanitoyannis

- Journals - El Sevier, Journal of Food Quality, Trends in Food Science and Technology

- Government Websites - USDA/FDA/HHS

Group: AJ* and Priscilla - *AJ's Sandbox will be used for the group project.

Food Irradiation Article Review

- Is everything in the article relevant to the article topic? Is there anything that distracted you?

There was only one irrelevant point in the article, which was pertaining to irradiating medical devices. As the article is specifically called “Food Irradiation,” I felt that it was not relevant to article as medical devices would not fall under the umbrella of food. In my opinion, there was nothing greatly distracting in the article, however, felt that some topics were vague and could be elaborated upon - hence me being passionate about this article.

- Is the article neutral? Are there any claims, or frames, that appear heavily biased toward a particular position?

Although the article has a distinct “Public Perception” section, there are controversial claims throughout the article without a citation. Such examples include the safety and reactivity of irradiated foods. Although the claims are correct, they need proper citation and need to be edited so they portray the information in a neutral position.

- Are there viewpoints that are overrepresented, or underrepresented?

In my opinion, the article does a good job of laying down the basics of food irradiation but needs work in further explaining some sections including the “Public Perception” section stated above, “Treatment and Process” section and subsection respectively, and the “Timeline/History” section. Additionally, a greatly underrepresented section is the equipment used for irradiation, which would be added by our group. Lastly, the article is missing additional information regarding the three most common forms of irradiation, which would also be added by our group.

- Check a few citations. Do the links work? Does the source support the claims in the article?

There was a total of 106 citations, and after doing a citation check, I noticed multiple “Anonymous” references. There were also multiple sources with errors in the references mainly missing the reference title and date. Also, some links were not scientifically grounded and were from organizations for/against irradiation. Upon clicking on the links, there were two sources that I noticed with either incorrect links. The other references I clicked on (journal articles and government websites) were functioning and adequately supported the claims throughout the article.

- Is each fact referenced with an appropriate, reliable reference? Where does the information come from? Are these neutral sources? If biased, is that bias noted?

Each fact is not referenced with an appropriate, reliable reference. The article is missing references throughout and is minutely biased. The minor bias was noticed throughout, especially in regards to controversy/public perception of food irradiation. More so, the bias was noticed mainly on negative claims of irradiation, which would be correctly referenced by our group.

- Is any information out of date? Is anything missing that could be added?

Information is not out of date, but could be elaborated on with recent research on irradiation. Additionally, with technological advances and recent publications, the article could be improved.

- Check out the Talk page of the article. What kinds of conversations, if any, are going on behind the scenes about how to represent this topic?

There are three conversations going on in the “Talk” page - two of which have issues of references (under referencing sections and inadequate/unreliable references) while the third conversation discusses misleading phrases. There is also a “To-Do” list that can be elaborated upon.

- How is the article rated? Is it a part of any WikiProjects?

The article is an article of interest in the following three WikiProjects: WikiProject Medicine (B-class, low-importance), WikiProject Technology (B-class, no importance information), WikiProject Food and Drink (C-class, high-importance).

Evaluate how you can contribute to an existing article (create an outline indicating sections to improve), or contribute a new article (write the lead and create outline).

CURRENT Sections (hyperlinked and in blue); future contributions by group (denoted in black)

- 1 Uses - Priscilla

- Adding a more elaborate definition, incorporate the three commonly used modalities, hyperlink isotopes/alpha and beta particles/gamma photons

- 2 Public perception- move to later

- Add more neutral information regarding irradiation

- 3 Impact- not sure what this section is about, maybe remove?

- 3.1 Immediate effects-Change to direct and indirect effects

- 3.1.1 Misconceptions- Remove

- 3.1.2 Chemical changes

- Decay/half-life-this section is specifically for gamma sources

- Radiolytic products

- 3.1.3 Food quality

- 3.1.3.1 Quality Impact on Minimally Processed Vegetables

- Adding more examples of commonly irradiated foods (frog legs, pet treats, spices)

- 3.1.3.1 Quality Impact on Minimally Processed Vegetables

- 3.2 Long-term impacts

- 3.2.1 Misconceptions-Remove

- Adding more neutral information regarding irradiation

- 3.2.1 Misconceptions-Remove

- 3.3 Indirect effects of irradiation

- 3.1 Immediate effects-Change to direct and indirect effects

- 4 Treatment - Priscilla

- 4.1 Process

- More information about Cobalt-60 as a source of irradiating

- Add "Mechanism of Action" section

- Direct effects

- Indirect effects

- 4.2 Dosimetry

- Incorporating frequently used parameters of foods added above

- 4.3 Technology

- Adding "Equipment" subsection describing the types of machines used

- 4.4 Cost

- 4.1 Process

- 5 Standards & regulations

- 5.1 Labeling

- Labeling as denoted by USDA and FDA - "treated with/by"; irradiated foods that do not require labeling (restaurants)

- Add a "Packaging" section? - AJ

- 5.2 Food safety

- 5.3 Nuclear safety and security

- 5.1 Labeling

- 6 Irradiated food supply

- 7 Timeline of the history of food irradiation

- Updating history from 2011 to present and also elaborating on current bullet points where necessary - AJ

- 8 See also

- 9 Notes

- 10 References

- 11 Further reading

- 12 External links

**Improvements throughout:

- Remove irrelevant and biased claims

- Improve citations with dependable and appropriate references from sites stated above (try to remove any/all unreliable and biased references)

AJ: units related to food irradiation, advantages and disadvantages of food irradiation, packaging associated to food irradiation, and recent history.

Priscilla: lead, treatment, uses

Food irradiation is the process of exposing food and food packaging to ionizing radiation. Ionizing radiation, such from gamma rays, x-rays or electron beams, is energy that can be transmitted without direct contact to the source of the energy (radiation) capable of freeing electrons from their atomic bonds (ionization) in the targeted food. The radiation can be emitted by a radioactive substance or generated electrically. This treatment is used to improve food safety by extending product shelf-life (preservation), reducing the risk of foodborne illness, delaying or eliminating sprouting or ripening, by sterilization of foods, and as a means of controlling insects and invasive pests. Food irradiation primarily extends the shelf-life of irradiated foods by effectively destroying organisms responsible for spoilage and foodborne illness and inhibiting sprouting. Although consumer perception of foods treated with irradiation are generally negative when compared with those processed by other means due to the misconception that food becomes radioactive or mutated, all independent research, the U.S. Food and Drug Administration (FDA), the World Health Organization (WHO), the Center for Disease Control and Prevention (CDC), and U.S. Department of Agriculture (USDA) have confirmed irradiation to be safe.

Food irradiation is permitted by over 60 countries, with about 500,000 metric tons of food annually processed worldwide. The regulations that dictate how food is to be irradiated, as well as the food allowed to be irradiated, vary greatly from country to country. In Austria, Germany, and many other countries of the European Union only dried herbs, spices, and seasonings can be processed with irradiation and only at a specific dose, while in Brazil all foods are allowed at any dose.

Contents[edit]

[hide]

- 1Uses

- 2Impact

- 3Treatment

- 4Standards & regulations

- 5Irradiated food supply

- 6Public perception

- 7Timeline of the history of food irradiation

- 8See also

- 9Notes

- 10References

- 11Further reading

- 12External links

Uses[edit][edit]

Irradiation is used to reduce or eliminate the risk of food-borne illnesses, prevent or slow down spoilage, arrest maturation or sprouting and as a treatment against pests. Depending on the dose, some or all of the pathogenic organisms, microorganisms, bacteria, and viruses present are destroyed, slowed down, or rendered incapable of reproduction. Irradiation cannot revert spoiled or over ripened food to a fresh state. If this food was processed by irradiation, further spoilage would cease and ripening would slow down, yet the irradiation would not destroy the toxins or repair the texture, color, or taste of the food. When targeting bacteria, most foods are irradiated to significantly reduce the number of active microbes, not to sterilize all microbes in the product. In this respect it is similar to pasteurization.

Irradiation is used to create safe foods for people at high risk of infection, or for conditions where food must be stored for long periods of time and proper storage conditions are not available. Foods that can tolerate irradiation at sufficient doses are treated to ensure that the product is completely sterilized. This is most commonly done with rations for astronauts, and special diets for hospital patients.

Irradiation is used to create shelf-stable products. Since irradiation reduces the populations of spoilage microorganisms, and because pre-packed food can be irradiated, the packaging prevents recontamination into the final product.

Irradiation is used to reduce post-harvest losses. It reduces populations of spoilage micro-organisms in the food and can slow down the speed at which enzymes change the food, and therefore slows spoilage and ripening, and inhibits sprouting (e.g., of potato, onion, and garlic).

Food is also irradiated to prevent the spread of invasive pest species through trade in fresh vegetables and fruits, either within countries, or trade across international boundaries. Pests such as insects could be transported to new habitats through trade in fresh produce which could significantly affect agricultural production and the environment were they to establish themselves. This "phytosanitary irradiation" aims to render any hitch-hiking pest incapable of breeding. The pests are sterilized when the food is treated by low doses of irradiation. In general, the higher doses required to destroy pests such as insects, mealybugs, mites, moths, and butterflies either affect the look or taste, or cannot be tolerated by fresh produce. Low dosage treatments (less than 1000 gray) enables trade across quarantine boundaries and may also help reduce spoilage.

Treatment[edit][edit]

Up to the point where the food is processed by irradiation, the food is processed in the same way as all other food. To treat the food, they are exposed to a radioactive source, for a set period of time to achieve a desired dose. Radiation may be emitted by a radioactive substance, or by X-ray and electron beam accelerators. Special precautions are taken to ensure the food stuffs never come in contact with the radioactive substances and that the personnel and the environment are protected from exposure radiation. Irradiation treatments are typically classified by dose (high, medium, and low), but are sometimes classified by the effects of the treatment (radappertization, radicidation and radurization). Food irradiation is sometimes referred to as "cold pasteurization" or "electronic pasteurization" because ionizing the food does not heat the food to high temperatures during the process, and the effect is similar to heat pasteurization. The term "cold pasteurization" is controversial because the term may be used to disguise the fact the food has been irradiated and pasteurization and irradiation are fundamentally different processes.

Treatment costs vary as a function of dose and facility usage. A pallet or tote is typically exposed for several minutes to hours depending on dose. Low-dose applications such as disinfestation of fruit range between US$0.01/lbs and US$0.08/lbs while higher-dose applications can cost as much as US$0.20/lbs.

Process[edit][edit]

Typically, when the food is being irradiated, pallets of food are exposed to a source of radiation for a specific time. Dosimeters are placed on the pallet (at various locations) of food to serve as a check and ensure that the correct dose was achieved. Most irradiated food is processed by gamma irradiation., however the usage of electron beam and X-ray is becoming more popular as well [1]. With gamma irradiation, special precautions are taken because gamma rays are continuously emitted by the radioactive material. In most designs, to nullify the effects of radiation, the radioisotope is lowered into a water-filled storage pool, which absorbs the radiation but does not become radioactive. This allows pallets of the products to be added and removed from the irradiation chamber and other maintenance to be done. Sometimes movable shields are used to reduce radiation levels in areas of the irradiation chamber instead of submerging the source.[citation needed] For x-ray and electron irradiation these precautions are not necessary as the radiation is generated by electricity, the source of the radiation can be switched off.

For x-ray, gamma ray and electron irradiation, shielding is required when the foods are being irradiated. This is done to protect workers and the environment outside of the chamber from radiation exposure. Typically permanent or movable shields are used. In some gamma irradiators the radioactive source is under water at all times, and the hermetically sealed product is lowered into the water. The water acts as the shield in this application.[citation needed] Because of the lower penetration depth of electron irradiation, treatment to entire industrial pallets or totes is not possible.[citation needed]

Dosimetry[edit][edit]

The radiation absorbed dose is the amount energy absorbed per unit weight of the target material. Dose is used because, when the same substance is given the same dose, similar changes are observed in the target material. The SI unit for dose is grays (Gy or J/kg). Dosimeters are used to measure dose, and are small components that, when exposed to ionizing radiation, change measurable physical attributes to a degree that can be correlated to the dose received. Measuring dose (dosimetry) involves exposing one or more dosimeters along with the target material.

For purposes of legislation doses are divided into low (up to 1 kGy), medium (1 kGy to 10 kGy), and high-dose applications (above 10 kGy).[citation needed] High-dose applications are above those currently permitted in the US for commercial food items by the FDA and other regulators around the world. Though these doses are approved for non commercial applications, such as sterilizing frozen meat for NASA astronauts (doses of 44 kGy) and food for hospital patients.

| Application | Dose (kGy) | |

|---|---|---|

| Low dose (up to 1 kGy) | Inhibit sprouting of bulbs and tubers | 0.03–0.15 kGy |

| Delay fruit ripening | 0.03–0.15 kGy | |

| Stop insect/parasite infestations to help clear quarantine | 0.07–1.00 kGy | |

| Medium dose (1 kGy to 10 kGy) | Delay spoilage of meat | 1.50–3.00 kGy |

| Reduce risk of pathogens in meat | 3.00–7.00 kGy | |

| Increase sanitation of spices | 10.00 kGy | |

| High dose (above 10 kGy) | Sterilization of packaged meat | 25.00–70.00 kGy |

| Increase juice yield[citation needed] | ||

| Improve re-hydration[citation needed] |

Technology[edit][edit]

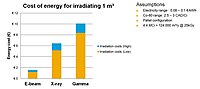

Efficiency illustration of the different radiation technologies (electron beam, X-ray, gamma rays) See also: Electron beam processing

Electron irradiation uses a stream of electrons accelerated by an electric voltage or radio frequency wave to a velocity close to the speed of light. Electrons have mass and negative electric charge, and therefore electron beams at the energies allowed for food irradiation do not penetrate into the product beyond several centimeters, depending on product density. Therefore, electron beams are preferred for thin products

Gamma irradiation involves packets of light (photons) that originate from radioactive decay of atomic nuclei. Gamma rays are used for products that are too thick for treatment with electron beams. Every radioactive element gives rise to Gamma rays with specific energies characteristic of the source element, these rays have zero mass and no electrical charge. The ones used for food irradiation are able to penetrate through food products. The radioactive isotope radioisotope cobalt-60 is used as the source in all commercial scale gamma irradiation facilities. Gamma irradiation is most widely used technology because the deeper penetration of the gamma rays enables administering treatment to entire industrial pallets or totes (reducing the need for material handling) and it is significantly less expensive than using an X-ray source. Cobalt-60 is bred from cobalt-59 using neutron irradiation in specifically designed nuclear reactors. In limited applications caesium-137, a less costly alternative recovered during the processing of spent nuclear fuel, is used as a radioactive source. Insufficient quantities are available for large scale commercial use. An incident where water-soluble caesium-137 leaked into the source storage pool requiring NRC intervention has led to near elimination of this radioisotope.

Irradiation by X-ray is similar to irradiation by gamma rays but the rays produced have a distribution of energetic packets of light, still the maximum energy of the produced X-ray photon is limited by the energy put into the X-ray generator therefore it is possible to guarantee that no partials capable of inducing irradiation can be emitted. X-rays are generated by colliding accelerated electrons with a dense target material (this process is known as bremsstrahlung-conversion), and the X-rays so produced have a spectrum characteristic of the dense target material. Heavy metals, such as tantalum and tungsten, are used because of their high atomic numbers and high melting temperatures. Tantalum is usually preferred versus tungsten for industrial, large-area, high-power targets because it is more workable than tungsten and has a higher threshold energy for induced reactions. Like electron beams, X-rays do not necessitate the use of radioactive materials and can be switched off when not needed. X-rays ability to penetrate the target is similar to gamma irradiation. X-ray machines produce better dose uniformity than Gamma rays, and their penetration depth is similar to slightly greater than that of gamma rays, but they require much more electricity as only as much as 12% of the input energy is converted into X-rays.

Cost[edit][edit]

The cost of food irradiation is influenced by dose requirements, volume and type of product, type and efficiency of radiation source, the food's tolerance of radiation, handling conditions, i.e., packaging and stacking requirements, construction costs, financing arrangements, and other variables particular to the situation. In the case of large research or contract irradiation facilities, major capital costs include a radiation source, hardware (irradiator, totes and conveyors, control systems, and other auxiliary equipment), land (1 to 1.5 acres), radiation shield, and warehouse. Irradiation is a capital-intensive technology requiring a substantial initial investment, ranging from $1 million to $5 million. Operating costs include salaries (for fixed and variable labor), utilities, maintenance, taxes/insurance, cobalt-60 replenishment, general utilities, and miscellaneous operating costs. Perishable food items, like fruits, vegetables and meats would still require to be handled in the cold chain, so all other supply chain costs remain the same. In the United States, the cost of food irradiation ranges between $0.02 and $0.40 per kilogram, varying depending on all the variables associated with irradiation. http://apps.who.int/iris/bitstream/handle/10665/38544/9241542403_eng.pdf;jsessionid=43101AD4C8312A2CC88E6287FCE1504D?sequence=1

Impact[edit] --> *Change name to "Effects of Food Irradiation" (section moved to later)[edit]

Irradiation reduces the risk of infection and spoilage, does not make food radioactive, and the food is shown to be safe, but it does cause chemical reactions that alter the food and therefore alters the chemical makeup, nutritional content, and the sensory qualities of the food. Some of the potential secondary impacts of irradiation are hypothetical, while others are demonstrated. These effects include cumulative impacts to pathogens, people, and the environment due to the reduction of food quality, the transpiration and storage of radioactive goods, and destruction of pathogens, changes in the way we relate to food and how irradiation changes the food production and shipping industries.

Irradiation primarily extends product shelf-life by destruction of spoilage and pathogenic microorganisms, delay of sprouting, and disinfestation.[1] Low, medium, and high doses of ionizing energy have shown to be safe and do not make food radioactive. Irradiation causes chemical reactions that result in alteration of the chemical makeup, nutritional content, and sensory qualities of the irradiated food. Consequences of food irradiation include direct and indirect effects, effect on microorganisms, effect on nutrition, and toxicological and radiolytic chemical products.

Immediate effects[edit] **Change to "Direct and indirect effects"[edit]

The radiation source supplies energetic particles or waves. As these waves/particles pass through a target material they collide with other particles. Around the sites of these collisions chemical bonds are broken, creating short lived radicals (e.g. the hydroxyl radical, the hydrogen atom and solvated electrons). These radicals cause further chemical changes by bonding with and or stripping particles from nearby molecules. When collisions damage DNA or RNA, effective reproduction becomes unlikely, also when collisions occur in cells, cell division is often suppressed.

Irradiation (within the accepted energy limits, as 10 MeV for electrons, 5 MeV for X-rays [US 7.5 MeV] and gamma rays from Cobalt-60) can not make food radioactive, but it does produce radiolytic products, and free radicals in the food. A few of these products are unique, but not considered dangerous.

Irradiation can also alter the nutritional content and flavor of foods, much like cooking. The scale of these chemical changes is not unique. Cooking, smoking, salting, and other less novel techniques, cause the food to be altered so drastically that its original nature is almost unrecognizable, and must be called by a different name. Storage of food also causes dramatic chemical changes, ones that eventually lead to deterioration and spoilage.

The radiation source supplies energetic particles or waves. As these waves/particles pass through a target material they collide with other particles. Around the sites of these collisions chemical bonds are broken, creating short lived radicals (e.g. hydroxyl radical). These radicals cause further chemical changes by bonding with and or stripping particles from nearby molecules. When collisions damage DNA or RNA, effective reproduction becomes unlikely, also when collisions occur in cells, cell division is often suppressed.

- How does irradiation work?

- Compton

- Direct: "due to direct contact of high energy with specific molecule or cell (DNA) --> nonfunctional = death"

- Indirect: "produce ion pairs and free radicals, produced mostly by products of water radiolysis, hydroxyl radicals (strong oxidizing agents), solvated electrons (strong reducing agent), hydrogen radicals (strong reducing)"

Effect on microorganisms

Through the use of ionizing energy, irradiation produces deadly effects on microorganisms. Such effects include changes in DNA, RNA, cell membrane structure, and metabolic enzyme activity. DNA and RNA are vital components in the cell nuclei required for cell growth and replication. By altering cell membranes and metabolic enzyme activity, reactive ions injure or destroy microorganisms.[1] Upon treatment, cells fail to replicate due to damage in the DNA and the double helix of the DNA being unable to uncoil to begin replication.[1] Ion production and interaction with DNA greatly determine the damage and rate of destruction of microorganisms, while reduction on cell numbers depends on irradiation dose used for treatment.[1] Sensitivity to radiation is determined in a D10-value. D10-value is defined as the amount of radiation treatment required to reduce the population of a certain microorganism by 90%.[1] The D10-value depends on the bacterium, but is affected by temperature, growth medium, and moisture content. Higher temperatures, simpler growth mediums, and increased moisture content result in decreased D10-values.

Food quality[edit][edit]

Ionizing radiation can change food quality such as nutritional and sensory contents only when very high levels of radiation treatment are used. Commercially, irradiation doses (1-10 kGy) have minimal negative impact on the sensory qualities and nutrient content in foods. However, approved dosages should not be used to replace adequate good manufacturing practices (GMPs), nor are sufficient to successfully sterilize the food product.[2] As a non-thermal process, irradiation keeps nutritional and sensory qualities originally associated with the food product.

Original qualities of the food include macronutrients (carbohydrates, proteins, and lipids), taste, color, and texture. Physical attributes associated with common carbohydrates such as pectin, starch, and gums are greatly affected by irradiation, thereby changing the functionality of the carbohydrates; however, the degree of utilization of the carbohydrates remain unchanged therefore no change in nutritional value is observed.[1] Amino acids that comprise proteins, remain in the same composition and digestible at commercial levels of irradiation.[1] When exposed to high doses of radiation, sulfur containing amino acids methionine and cysteine can change the aroma and taste of food because of oxidation.[1] Foods with high fat content result in lipid oxidation, which produce off-flavors and off-aromas due to byproducts of lipid oxidation- hydroperoxides.[1] Propagation of lipid oxidation in high fat foods makes those foods unsuitable for irradiation due to the quick rancidity. Color, especially in meat and fish, can be altered by irradiation due to oxidation of myoglobin by radiolytic products.

Micronutrients in food irradiated products express similar effects to those of foods processed with other methods- minimally inactivated.[1] This holds especially true for vitamins such as thiamine, ascorbic acid, pyridoxine, retinol, and α-tocopherol.[2] Vitamin inactivation is dependent on the vitamin itself along with dosage and type of product used for irradiation. Water-soluble Vitamin D and Vitamin K are mainly unaffected by irradiation while Vitamin A and Vitamin E are sensitive to radiation.[1]

Sensory qualities such as color, taste, texture, and appearance are not significantly affected by irradiation.[2] Conversely, irradiated celery was found to be superior than untreated celery and blanched, acidified, and chlorinated celery.[3] As for taste, similar to other processes, irradiation can minimally alter the taste of the food. Foods especially sensitive to changes in flavor and color are poultry and pork products.[2] Due to major sensory changes, foods like eggs, milk, dairy, and certain fruits/vegetables, are unsuitable because of volatile off-flavors produced as a result of irradiation.[2]

Although changes in nutritional and sensory qualities by irradiation depend greatly on the degree of treatment and vary among foods, it is well researched that irradiation does not pose greater negative effects on food quality than any other food processing technology.[1]

Chemical changes[edit][edit]

Irradiation does not make food radioactive, but does form radiolytic products (hydrocarbons, aldehydes, and ketones) from ions and free radicals as a result of the high energy. A few of these products are unique, but not considered dangerous. Most of the substances found in irradiated food are also found in food that has been subjected to other food processing treatments, and are therefore not greatly unique. One family of chemicals (2ACB's) are exclusively formed by irradiation (unique radiolytic products), but this product is non-toxic. When irradiating food, all products occur in a lower or comparable frequency to quantities produced by other food processing techniques.

Free radicals form when food is irradiated; however, these products are also present upon oxidation of foods. Most of these are oxidizers (i.e., accept electrons) and some react very strongly. According to the free-radical theory of aging excessive amounts of these free radicals can lead to cell injury and cell death, which may contribute to many diseases. However, this generally relates to the free radicals generated in the body, not the free radicals consumed by the individual, as much of these are destroyed in the digestive process.

The most unique radiolytic product is a family of compounds called 2-alkylcyclobutanones (2-ACBs) formed upon irradiating primarily fatty acids. Alkylcyclobutanones are products obtained only by irradiation as they are yet to be discovered as products in raw or heat-processed foods.[2] However, the genotoxicity of alkylcyclobutanones is yet to be determined, therefore the true impact of them as radiolytic products is unknown.[2] Irradiation, like other treatments, also produces furans, especially in juices high in sugar and acid, fresh fruits and vegetables, and apple cider.[2] Furans are known to be carcinogenic at high doses and are also a form of antioxidants. Furans are also commonly found in baby foods, infant formula, coffee, food mixtures (soups and sauces), fish, canned fruits and vegetables, nuts, and meats.[4] The amount of furans produced by irradiation is to a lesser extent than when foods are heat processed or simply stored under refrigeration.[2] Another carcinogen produced by irradiation of high doses is benzene.[2] Benzene has been discovered in sterilized beef by irradiation, which used doses 35 times as the allowed dosage by regulation.[2]

It is important to remember that all chemical products of irradiation are dependent on the the food matrix and radiation dose used. Also, many of the chemicals produced by irradiation are in low concentrations and are not enough to create radioactive foods. All irradiation products, with the exception of 2-alkylcyclobutanones are also produced by other food processes. Only extremely high doses of chemical products will have carcinogenic effects.The radiation doses to cause toxic changes are much higher than the doses used to during irradiation, and taking into account the presence of 2-ACBs along with what is known of free radicals, these results lead to the conclusion that there is no significant risk from radiolytic products.

Long-term impacts[edit][edit]

If the majority of food was irradiated at high-enough levels to significantly decrease its nutritional content, there would be an increased risk of developing nutritionally-based illnesses if additional steps, such as changes in eating habits, were not taken to mitigate this. Furthermore, for at least three studies on cats, the consumption of irradiated food was associated with a loss of tissue in the myelin sheath, leading to reversible paralysis. Researchers suspect that reduced levels of vitamin A and high levels of free radicals may be the cause. This effect is thought to be specific to cats and has not been reproduced in any other animal. To produce these effects, the cats were fed solely on food that was irradiated at a dose at least five times higher than the maximum allowable dose.

It may seem reasonable to assume that irradiating food might lead to radiation-tolerant strains, similar to the way that strains of bacteria have developed resistance to antibiotics. Bacteria develop a resistance to antibiotics after an individual uses antibiotics repeatedly. Much like pasteurization plants, products that pass through irradiation plants are processed once, and are not processed and reprocessed. Cycles of heat treatment have been shown to produce heat-tolerant bacteria, yet no problems have appeared so far in pasteurization plants. Furthermore, when the irradiation dose is chosen to target a specific species of microbe, it is calibrated to doses several times the value required to target the species. This ensures that the process randomly destroys all members of a target species. Therefore, the more irradiation-tolerant members of the target species are not given any evolutionary advantage. Without evolutionary advantage, selection does not occur. As to the irradiation process directly producing mutations that lead to more virulent, radiation-resistant strains, the European Commission's Scientific Committee on Food found that there is no evidence; on the contrary, irradiation has been found to cause loss of virulence and infectivity, as mutants are usually less competitive and less adapted.

Indirect effects of irradiation[edit][edit]

The indirect effects of irradiation are the concerns and benefits of irradiation that are related to how making food irradiation a common process will change the world, with emphasis on the system of food production.

If irradiation was to become common in the food handling process there would be a reduction of the prevalence of foodborne illness and potentially the eradication of specific pathogens. However, multiple studies suggest that an increased rate of pathogen growth may occur when irradiated food is cross-contaminated with a pathogen, as the competing spoilage organisms are no longer present. This being said, cross contamination itself becomes less prevalent with an increase in usage of irradiated foods.

The ability to remove bacterial contamination through post-processing by irradiation may reduce the fear of mishandling food which could cultivate a cavalier attitude toward hygiene and result in contaminants other than bacteria. However, concerns that the pasteurization of milk would lead to increased contamination of milk were prevalent when mandatory pasteurization was introduced, but these fears never materialized after adoption of this law. Therefore, it is unlikely for irradiation to cause an increase of illness due to nonbacteria-based contamination.

Quality Impact on Minimally Processed Vegetables[edit][edit]

Watercress (Nasturtium Officinale) is a rapidly growing aquatic or semi aquatic perennial plant. Because chemical agents do not provide efficient microbial reductions, watercress has been tested with gamma irradiation treatment in order to improve both safety and the shelf life of the product. It is traditionally used on horticultural products to prevent sprouting and post-packaging contamination, delay post-harvest ripening, maturation and senescence.

In a Food Chemistry food journal, scientists studied the suitability of gamma irradiation of 1, 2, and 5 kGy for preserving quality parameters of the fresh cut watercress at around 4 degrees Celsius for 7 days. They determined that a 2 kGy dose of irradiation was the dose that contained most similar qualities to non-stored control samples, which is one of the goals of irradiation. 2 kGy preserved high levels of reducing sugars and favoured PUFA; while samples of the 5 kGy dose revealed high contents of sucrose and MUFA. Both cases the watercress samples obtained healthier fatty acids profiles. However, a 5kGy dose better preserved the antioxidant activity and total flavonoids.

***Remove entire section (irrelevant to topic)

Standards & regulations[edit][edit]

The Codex Alimentarius represents the global standard for irradiation of food, in particular under the WTO-agreement. Member states are free to convert those standards into national regulations at their discretion,[citation needed] therefore regulations about irradiation differ from country to country.

The United Nations Food and Agricultural Organization (FAO) has passed a motion to commit member states to implement irradiation technology for their national phytosanitary programs; the General assembly of the International Atomic Energy Agency (IAEA) has urged wider use of the irradiation technology.[citation needed]

Labeling[edit][edit]

The Radura symbol, as required by U.S. Food and Drug Administration regulations to show a food has been treated with ionizing radiation. The provisions of the Codex Alimentarius are that any "first generation" product must be labeled "irradiated" as any product derived directly from an irradiated raw material; for ingredients the provision is that even the last molecule of an irradiated ingredient must be listed with the ingredients even in cases where the unirradiated ingredient does not appear on the label. The RADURA-logo is optional; several countries use a graphical version that differs from the Codex-version. The suggested rules for labeling is published at CODEX-STAN – 1 (2005), and includes the usage of the Radura symbol for all products that contain irradiated foods. The Radura symbol is not a designator of quality. The amount of pathogens remaining is based upon dose and the original content and the dose applied can vary on a product by product basis.

The European Union follows the Codex's provision to label irradiated ingredients down to the last molecule of irradiated food. The European Community does not provide for the use of the Radura logo and relies exclusively on labeling by the appropriate phrases in the respective languages of the Member States. The European Union enforces its irradiation labeling laws by requiring its member countries to perform tests on a cross section of food items in the market-place and to report to the European Commission. The results are published annually in the OJ of the European Communities.

The US defines irradiated foods as foods in which the irradiation causes a material change in the food, or a material change in the consequences that may result from the use of the food. Therefore, food that is processed as an ingredient by a restaurant or food processor is exempt from the labeling requirement in the US. All irradiated foods must include a prominent Radura symbol followed in addition to the statement "treated with irradiation" or "treated by irradiation. Bulk foods must be individually labeled with the symbol and statement or, alternatively, the Radura and statement should be located next to the sale container.

Organic advocacy groups believe that irradiated food should not be labeled as raw because they believe the process changes the nutritional content of food. However, the degradation of vitamins caused by irradiation is similar to or even less than the loss caused by other raw food preservation processes. Other processes like chilling, freezing, drying, and heating also result in some vitamin loss.

Food safety[edit][edit]

In 2003, the Codex Alimentarius removed any upper dose limit for food irradiation as well as clearances for specific foods, declaring that all are safe to irradiate. Countries such as Pakistan and Brazil have adopted the Codex without any reservation or restriction. Other countries, including New Zealand, Australia, Thailand, India, and Mexico, have permitted the irradiation of fresh fruits for fruit fly quarantine purposes, amongst others.[citation needed]

Standards that describe calibration and operation for radiation dosimetry, as well as procedures to relate the measured dose to the effects achieved and to report and document such results, are maintained by the American Society for Testing and Materials (ASTM international) and are also available as ISO/ASTM standards.

All of the rules involved in processing food are applied to all foods before they are irradiated.

United States[edit][edit]

The U.S. Food and Drug Administration (FDA) is the agency responsible for regulation of radiation sources in the United States. Irradiation, as defined by the FDA is a "food additive" as opposed to a food process and therefore falls under the food additive regulations. Each food approved for irradiation has specific guidelines in terms of minimum and maximum dosage as deterred safe by the FDA. Packaging materials containing the food processed by irradiation must also undergo approval. The United States Department of Agriculture (USDA) amends these rules for use with meat, poultry, and fresh fruit.

The United States Department of Agriculture (USDA) has approved the use of low-level irradiation as an alternative treatment to pesticides for fruits and vegetables that are considered hosts to a number of insect pests, including fruit flies and seed weevils. Under bilateral agreements that allows less-developed countries to earn income through food exports agreements are made to allow them to irradiate fruits and vegetables at low doses to kill insects, so that the food can avoid quarantine.

European Union[edit][edit]

European law dictates that all member countries must allow the sale of irradiated dried aromatic herbs, spices and vegetable seasonings. However, these Directives allow Member States to maintain previous clearances food categories the EC's Scientific Committee on Food (SCF) had previously approved (the approval body is now the European Food Safety Authority). Presently, Belgium, Czech Republic, France, Italy, Netherlands, Poland, and the United Kingdom allow the sale of many different types of irradiated foods. Before individual items in an approved class can be added to the approved list, studies into the toxicology of each of such food and for each of the proposed dose ranges are requested. It also states that irradiation shall not be used "as a substitute for hygiene or health practices or good manufacturing or agricultural practice". These Directives only control food irradiation for food retail and their conditions and controls are not applicable to the irradiation of food for patients requiring sterile diets.

Because of the Single Market of the EC any food, even if irradiated, must be allowed to be marketed in any other Member State even if a general ban of food irradiation prevails, under the condition that the food has been irradiated legally in the state of origin. Furthermore, imports into the EC are possible from third countries if the irradiation facility had been inspected and approved by the EC and the treatment is legal within the EC or some Member state.

Australia[edit][edit]

Australia banned irradiated cat food after a national scare where cats suffered from paralyzation after eating a specific brand of highly irradiated catfood for an extended period of time. The suspected culprit was malnutrition from consuming food depleted of Vitamin A by the irradiation process. The incident was linked only to a single batch of one brand's product and no illness was linked to any of that brand's other irradiated batches of the same product or to any other brand of irradiated cat food. This, along with incomplete evidence indicating that the cat food was not sufficiently depleted of Vitamin A makes irradiation a less likely cause. Further research has been able to experimentally induce the paralyzation of cats by via Vitamin A deficiency by feeding highly irradiated food. For more details see the Long term impacts section.

Nuclear safety and security[edit][edit]

Interlocks and safeguards are mandated to minimize this risk. There have been radiation-related accidents, deaths, and injury at such facilities, many of them caused by operators overriding the safety related interlocks.In a radiation processing facility, radiation specific concerns are supervised by special authorities, while "Ordinary" occupational safety regulations are handled much like other businesses.

The safety of irradiation facilities is regulated by the United Nations International Atomic Energy Agency and monitored by the different national Nuclear Regulatory Commissions. The regulators enforce a safety culture that mandates that all incidents that occur are documented and thoroughly analyzed to determine the cause and improvement potential. Such incidents are studied by personnel at multiple facilities, and improvements are mandated to retrofit existing facilities and future design.

In the US the Nuclear Regulatory Commission (NRC) regulates the safety of the processing facility, and the United States Department of Transportation (DOT) regulates the safe transport of the radioactive sources.

Irradiated food supply[edit][edit]

Food irradiation is permitted by over 60 countries, with about 500,000 metric tons of food annually processed worldwide. The regulations that dictate how food is to be irradiated, as well as the food allowed to be irradiated, vary greatly from country to country. In Austria, Germany, and many other countries of the European Union only dried herbs, spices, and seasonings can be processed with irradiation and only at a specific dose, while in Brazil all foods are allowed at any dose.

As of 2010, the quantities of foods irradiated in Asia, the EU and the US were 285,200, 9,300, and 103,000 tons. Authorities in some countries use tests that can detect the irradiation of food items to enforce labeling standards and to bolster consumer confidence. The European Union monitors the market to determine the quantity of irradiated foods, if irradiated foods are labeled as irradiated, and if the irradiation is performed at approved facilities.

Irradiation of fruits and vegetables to prevent the spread of pest and diseases across borders has been increasing globally. In 2010, 18,446 tonnes of fruits and vegetables were irradiated in six countries for export quarantine control. 97% of this was exported to the United States.

In total, 103 000 tonnes of food products were irradiated on mainland United States in 2010. The three types of foods irradiated the most were spices (77.7%), fruits and vegetables (14.6%) and meat and poultry (7.77%). 17 953 tonnes of irradiated fruits and vegetables were exported to the mainland United States. Mexico, the United States' state of Hawaii, Thailand, Vietnam and India export irradiated produce to the mainland U.S.Mexico, followed by the United States' state of Hawaii, is the largest exporter of irradiated produce to the mainland U.S.

In total, 6 876 tonnes of food products were irradiated in European Union countries in 2013; mainly in four member state countries: Belgium (49.4%), the Netherlands (24.4%), Spain (12.7%) and France (10.0%). The two types of foods irradiated the most were frog legs (46%), and dried herbs and spices (25%). There has been a decrease of 14% in the total quantity of products irradiated in the EU compared to the previous year 2012 (7 972 tonnes).

There has been low level gamma irradiation that has been attempted on arugula, spinach, cauliflower, ash gourd, bamboo shoots, coriander, parsley, and watercress. There has been limited information, however, regarding the physical, chemical and/or bioactive properties and the shelf life on these minimally processed vegetables.

United States[edit][edit]

The U.S. Food and Drug Administration and the U.S. Department of Agriculture have approved irradiation of the following foods and purposes:

- Packaged refrigerated or frozen red meat — to control pathogens (E. Coli O157:H7 and Salmonella) and to extend shelf life.

- Packaged poultry — control pathogens (Salmonella and Camplylobacter).

- Fresh fruits, vegetables, and grains — to control insects and inhibit growth, ripening and sprouting.

- Pork — to control trichinosis.

- Herbs, spices and vegetable seasonings — to control insects and microorganisms.

- Dry or dehydrated enzyme preparations — to control insects and microorganisms.

- White potatoes — to inhibit sprout development.

- Wheat and wheat flour — to control insects.

- Loose or bagged fresh iceberg lettuce and spinach

- Crustaceans (lobster, shrimp, and crab)

- Shellfish (oysters, clams, mussels, and scallops)

UK

The Food Standards Agency (FSA) allows irradiation on the following general food categories (and maximum dosage allowed):[5]

- Fruit (2 kGy)

- Vegetables (1 kGy)

- Cereals (1kGy)

- Bulbs and tubers (0.2 kGy)

- Dried aromatic herbs, spices and vegetable seasonings (10 kGy)

- Fish and shellfish (3 kGy)

- Poultry (7 kGy)

https://www.food.gov.uk/science/irradfoodqa

Canada

With the exception of the foods listed below, the Canadian Food Inspection Agency does not allow irradiation of food in Canada:[6]

- Potatoes

- Onions

- Wheat, flour, whole wheat flour

- Whole or ground spices and dehydrated seasoning preparations

- Fresh raw ground beef

- Frozen raw ground beef

- http://www.inspection.gc.ca/food/labelling/food-labelling-for-industry/irradiated-foods/eng/1334594151161/1334596074872

China

National standards for food irradiation (and maximum dosage allowed) in China are the following:[7]

- Poultry and livestock, cooked (8 kGy)

- Pollen (8 kGy)

- Dried nuts and preserved fruits (0.4-1 kGy)

- Spices (10 kGy)

- Fresh fruits and vegetables (1.5 kGy)

- Pork (0.65 kGy)

- Beans and bean products (0.2 kGy)

- http://iiaglobal.com/uploads/IMRP2013/0.7_Food_Irradiation_Strand/FI3-1_CHEN_Hao.pdf

EU

The European Commission has approved the use of food irradiation in the following products:[8]

- Fruits and vegetables

- Cereals and rice flour

- Spices and condiments

- Fish and shellfish

- Fresh meats, poultry, and frog legs

- Raw milk camembert

- Gum arabic, casein, and egg whites

- Blood products

- https://ec.europa.eu/food/safety/biosafety/irradiation/legislation_en

Public perception[edit] **section merged with "Misconceptions" sections throughout article[edit]

A major concern is that irradiation might cause chemical changes that are harmful to the consumer. Several national expert groups and two international expert groups evaluated the available data and concluded that any food at any dose is wholesome and safe to consume as long as it remains palatable and maintains its technical properties (e.g. feel, texture, or color). While irradiation can cause many products, it is important to remember that the low concentrations are not a health concern whatsoever. Consensus among scientific studies is that irradiation does not cause cancer.[2]

Irradiated food does not become radioactive, just as an object exposed to light does not start producing light. Radioactivity is the ability of a substance to emit high energy particles. When particles hit the target materials they may free other highly energetic particles. This ends shortly after the end of the exposure, much like objects stop reflecting light when the source is turned off and warm objects emit heat until they cool down but do not continue to produce their own heat. To modify a material so that it keeps emitting radiation (induce radiation) the atomic cores (nucleus) of the atoms in the target material must be modified. By only affecting the outermost electrons, foods treated with irradiation are not radioactive as irradiation does not provide enough energy to destabilize the nuclei of the food matrix. Irradiated foods absorb the processing energy and as a result, atoms get ionized, which is non-toxic. The energy used destroy bacteria but does not pose significant changes to the food itself.[2] Additionally, there is no evidence to conclude that the free radicals produced by irradiation of food alter the safety of food products.

Irradiation has been approved by many countries. For example, in the U.S. the FDA has approved food irradiation for over fifty years. However, in the past decade the major growth area is for fruits and vegetables that are irradiated to prevent the spread of pests. In the early 2000s in the US, irradiated meat was common at some grocery stores, but because of lack of consumer demand, it is no longer common. Because consumer demand for irradiated food is low, reducing the spoilage between manufacture and consumer purchase and reducing the risk of food borne illness is currently not sufficient incentive for most manufactures to supplement their process with irradiation. Nevertheless, food irradiation does take place commercially and volumes are in general increasing at a slow rate, even in the European Union where all member countries allow the irradiation of dried herbs spices and vegetable seasonings but only a few allow other foods to be sold as irradiated.

Although there are some consumers who choose not to purchase irradiated food, a sufficient market has existed for retailers to have continuously stocked irradiated products for years. When labeled irradiated food is offered for retail sale, these consumers buy and re-purchase it, indicating that it is possible to successfully market irradiated foods; therefore retailers not stocking irradiated foods might be a major bottleneck to the wider adoption of irradiated foods. It is however, widely believed that consumer perception of foods treated with irradiation is more negative than those processed by other means and some industry studies indicate the number of consumers concerned about the safety of irradiated food decreased between 1985 and 1995 to levels comparable to those of people concerned about food additives and preservatives. Even though is it is untrue "People think the product is radioactive," said Harlan Clemmons, president of Sadex, a food irradiation company based in Sioux City, Iowa. Because of these concerns and the increased cost of irradiated foods, there is not a widespread public demand for the irradiation of foods for human consumption. Irradiated food does not become radioactive.

Timeline of the history of food irradiation[edit][edit]

- 1895 Wilhelm Conrad Röntgen discovers X-rays ("bremsstrahlung", from German for radiation produced by deceleration)

- 1896 Antoine Henri Becquerel discovers natural radioactivity; Minck proposes the therapeutic use

- 1904 Samuel Prescott describes the bactericide effects Massachusetts Institute of Technology (MIT)

- 1906 Appleby & Banks: UK patent to use radioactive isotopes to irradiate particulate food in a flowing bed

- 1918 Gillett: U.S. Patent to use X-rays for the preservation of food

- 1921 Schwartz describes the elimination of Trichinella from food

- 1930 Wuest: French patent on food irradiation

- 1943 MIT becomes active in the field of food preservation for the U.S. Army

- 1951 U.S. Atomic Energy Commission begins to co-ordinate national research activities

- 1958 World first commercial food irradiation (spices) at Stuttgart, Germany

- 1970 Establishment of the International Food Irradiation Project (IFIP), headquarters at the Federal Research Centre for Food Preservation, Karlsruhe, Germany

- 1980 FAO/IAEA/WHO Joint Expert Committee on Food Irradiation recommends the clearance generally up to 10 kGy "overall average dose"

- 1981/1983 End of IFIP after reaching its goals

- 1983 Codex Alimentarius General Standard for Irradiated Foods: any food at a maximum "overall average dose" of 10 kGy

- 1984 International Consultative Group on Food Irradiation (ICGFI) becomes the successor of IFIP

- 1998 The European Union's Scientific Committee on Food (SCF) voted "positive" on eight categories of irradiation applications

- 1997 FAO/IAEA/WHO Joint Study Group on High-Dose Irradiation recommends to lift any upper dose limit

- 1999 The European Union issues Directives 1999/2/EC (framework Directive) and 1999/3/EC (implementing Directive) limiting irradiation a positive list whose sole content is one of the eight categories approved by the SFC, but allowing the individual states to give clearances for any food previously approved by the SFC.

- 2000 Germany leads a veto on a measure to provide a final draft for the positive list.

- 2003 Codex Alimentarius General Standard for Irradiated Foods: no longer any upper dose limit

- 2003 The SCF adopts a "revised opinion" that recommends against the cancellation of the upper dose limit.

- 2004 ICGFI ends

- 2011 The successor to the SFC, European Food Safety Authority (EFSA), reexamines the SFC's list and makes further recommendations for inclusion.

See also[edit][edit]

Deinococcus radioduransFood labeling regulationsFood and cooking hygieneIrradiated mailChemical sterilizationRadurization- ***Replace all current "See also" section with relevant readings

Notes[edit][edit]

^ Jump up to: a b c fresh or frozen red meat, poultry, and seafoodJump up ^ improve hygienic qualityJump up ^ shelf stable without refrigeration- ***Remove all notes

https://www.fda.gov/Food/IngredientsPackagingLabeling/IrradiatedFoodPackaging/ucm081050.htm

Despite its limited use in the past, use of food irradiation is increasing as consumers are beginning to appreciate the benefits of irradiated food.

| This is a user sandbox of Herna327. You can use it for testing or practicing edits. This is not the sandbox where you should draft your assigned article for a dashboard.wikiedu.org course. To find the right sandbox for your assignment, visit your Dashboard course page and follow the Sandbox Draft link for your assigned article in the My Articles section. |

- ^ a b c d e f g h i j k l Fellows, P.J. Food Processing Technology: Principles and Practices.

- ^ a b c d e f g h i j k l m "Food Irradiation A Guide for Consumers, Policymakers and the Media" (PDF).

- ^ Prakash, A.; Guner, A.R.; Caporaso, F.; Foley, D.M. (2000-04-01). "Effects of Low-dose Gamma Irradiation on the Shelf Life and Quality Characteristics of Cut Romaine Lettuce Packaged under Modified Atmosphere". Journal of Food Science. 65 (3): 549–553. doi:10.1111/j.1365-2621.2000.tb16046.x. ISSN 1750-3841.

- ^ Nutrition, Center for Food Safety and Applied. "Chemical Contaminants - Exploratory Data on Furan in Food: Individual Food Products". www.fda.gov. Retrieved 2018-04-19.

- ^ Agency, Food Standards. "Irradiated food | Food Standards Agency". www.food.gov.uk. Retrieved 2018-04-18.

- ^ Directorate, Government of Canada,Canadian Food Inspection Agency,Food Labelling and Claims. "Irradiated Foods". www.inspection.gc.ca. Retrieved 2018-04-18.

{{cite web}}: CS1 maint: multiple names: authors list (link) - ^ Chen, Hao (2013). "Food Irradiation in China" (PDF).

- ^ "Legislation - Food Safety - European Commission". Food Safety. Retrieved 2018-04-20.

Review/Feedback on Pasteurization Group (Arianna's Sandbox)

Lead Section

Introductory sentence - good (topic of article stated, though not concise/direct). The introductory sentence is very vague and difficult to understand due to the wording of it. By splitting up packaged and non-packaged foods as two different categories, I can sense some confusion by non-food science readers. Also, be more detailed in regards to what pathogens are commonly reduced and how shelf-life is extended. The first sentence is very important and can be take as a hook for readers - need to provide them with much detail from the beginning.

Summary - poor (missing/lacking key ideas). Review class notes, assigned readings, and articles on pasteurization to provide key ideas that we have learned regarding pasteurization.

Context - fair (includes only 1-2 additional sentences of information, yet doesn't provide enough information to determine what the article is about). Good starting history, but needs elaboration (too vague).

Lead section overall is vague and could use more pertinent information. Also, there are many pronouns (it, this, these, etc.) that can be elaborated upon. Lastly, in my opinion, the lead section is written as if the readers knew what we have learned throughout the semester as opposed to a lay audience.

Organization - fair (confusing organization and article does not flow between sections). Article should flow nicely from start to finish. There are sections that are started in the history and finished in the effects (milk). Group all pertinent ideas together and try not to skip around on subjects/food products. The history section of milk and alcoholic beverages is too in depth and distracting as it focuses on the history in the 1700's/1900's. Instead, a quick history of pasteurization should be incorporated and the article should focus on the principles of pasteurization. Possibly, include tables or diagrams explaining the process and common equipment of pasteurization and common parameters on multiple food products (not just milk and juice). We spent about two weeks learning about pasteurization and heat exchangers so look back at notes and improve/broaden that section. Definitely add more details regarding the effects of pasteurized foods.

Content - fair (covers some of the assigned topic area). See above comments on organization. Are sections of "Novel pasteurization" and "low moisture foods" pertinent to pasteurization? If so, I would change the section names as both can be associated with different articles. Instead of the linking products that are commonly pasteurized, elaborate on them and their common parameters and reasons for pasteurization. Make sure all the links in the "See also" section are relevant to pasteurization and are not just random food science terms.

Balance - excellent (article presents balanced coverage without favoring one side unduly). Good, neutral draft. As pasteurization is widely accepted, I cannot imagine negative articles on the subject, but group does a good job on not presenting the information as positive.

Tone - good (becomes informal or chatty in places). Check the tone throughout the draft. Remember, that the article should flow and the reader should not be able to differentiate between authors, which is currently the case. Also, as authors, let the writing reflect that we have a higher education and greater subject knowledge after taking this course.

Citations - fair (a few unsourced paragraphs or sections). Read carefully through your entire article to ensure that all ideas/information have been properly cited, even if they are paraphrased. Also, some sentences/paragraphs have unclear sourcing; again, thoroughly double check the article.

Sources - good (Article uses mostly good sources, but includes some lower-quality sources). The class book is a good start, but be sure to incorporate sources such as government websites (FDA/USDA) and books/sources from the library. LL has good resources, books are located on the third floor - take a look at what they have in terms of pasteurization.Try to stay away from journal articles as they may have a positive/negative tone towards the subject matter.

Completeness - fair (Most references are fairly complete, but some are missing something). Take a look at your references - should be a quick fix, there are two or three references that need to be updated. All others (including the few that I checked) are good to go.

New sections -

Re-organizing -

Gaps -

Smaller additions -

Coverage -

Article body -

Food Irradiation[edit]

Food irradiation is the process of exposing food and food packaging to ionizing radiation. Ionizing radiation, such as gamma rays, x-rays or electron beams, is energy that can be transmitted without direct contact to the source of the energy (radiation) capable of freeing electrons from their atomic bonds (ionization) in the targeted food.[1][2] Radiation can be emitted by a radioactive substance or generated electrically. This treatment is used to improve food safety by extending product shelf-life (preservation), reducing the risk of foodborne illness, delaying sprouting or ripening in fresh produce, sterilization of military foods, and as a means of controlling insects and invasive pests.[3] Food irradiation primarily extends the shelf-life of irradiated foods by effectively destroying pathogenic and spoilage organisms and inhibiting sprouting.[3] It does not involve significant heat treatment and thus maintains the sensory and nutritional aspects of the food.[4] Although consumer perception of foods treated with irradiation have been negative when compared with those processed by other means, all independent research, the U.S. Food and Drug Administration (FDA), the World Health Organization (WHO), the Center for Disease Control and Prevention (CDC), and U.S. Department of Agriculture (USDA) are among the organizations that have confirmed irradiation to be safe. [5][6][7][8][3][9][10][11][12][13]

Irradiation is also used for non-food applications, such as sterilization of medical devices, pharmaceuticals, and cosmetics.[4]

Uses[edit]

Irradiation is used to reduce or eliminate the risk of food-borne illnesses, prevent or slow down spoilage, delay germination or sprouting and as a treatment against foodborne insects and pests. Depending on the dose, some or all the pathogenic and spoilage microorganisms, viruses and pests present are destroyed, slowed down, or rendered incapable of reproduction.[14] At the doses (1-10 kGy) used, irradiation does not sterilize the food but pasteurizes it and hence irradiated food requires refrigeration.

Irradiation reduces postharvest losses by slowing down the rate of ripening. It inhibits spoilage microorganisms thus retarding spoilage of food. When used in low doses (0.06-0.2 kGy)[15], it prevents sprouting in fresh produce such as potatoes, onions, and garlic.

It is also used for the inactivation and control of parasites in meat and meat products. It is used to extend the shelf life of seafood, raw fresh fish, fruits, and vegetable and can be used as an alternative method of treatment for the decontamination of spices, herbs, and dry seasonings.

Phytosanitary irradiation, which is the use of ionizing radiation to prevent the spread of invasive insect pests by trade in fresh produce across national and international borders, is a growing field in food irradiation. These insects if allowed to enter new habitats, could establish themselves as pests in the normal environment and would be difficult to get rid of and cause significant damage to the agricultural production[16].

High doses of irradiation (greater than 10 kGy) are used by NASA to sterilize food intended for space flight programs (44 kGy)[17] and hospitals to sterilize foods in order to accomodate the diets of immunocompromised patients[18]. Irradiation can also be used to sterilize food packaging material[17].

Irradiation cannot revert spoiled or over ripened food to a fresh state. If this food was processed by irradiation, further spoilage would cease and ripening would slow down, yet the irradiation would not destroy the toxins or repair the texture, color, or taste of the food.[19] When targeting bacteria, most foods are irradiated to significantly reduce the number of active microbes, not to sterilize all microbes in the product. In this respect it is similar to pasteurization.

Irradiation is used to create safe foods for people at high risk of infection, or for conditions where food must be stored for long periods of time and proper storage conditions are not available. Foods that can tolerate irradiation at sufficient doses are treated to ensure that the product is completely sterilized. This is most commonly done with rations for astronauts, and special diets for hospital patients.

Irradiation is used to create shelf-stable products. Since irradiation reduces the populations of spoilage microorganisms, and because pre-packed food can be irradiated, the packaging prevents recontamination into the final product.[1]

Irradiation is used to reduce post-harvest losses. It reduces populations of spoilage micro-organisms in the food and can slow down the speed at which enzymes change the food, and therefore slows spoilage and ripening, and inhibits sprouting (e.g., of potato, onion, and garlic).[20]

Food is also irradiated to prevent the spread of invasive pest species through trade in fresh vegetables and fruits, either within countries, or trade across international boundaries. Pests such as insects could be transported to new habitats through trade in fresh produce which could significantly affect agricultural production and the environment were they to establish themselves. This "phytosanitary irradiation"[21] aims to render any hitch-hiking pest incapable of breeding. The pests are sterilized when the food is treated by low doses of irradiation. In general, the higher doses required to destroy pests such as insects, mealybugs, mites, moths, and butterflies either affect the look or taste, or cannot be tolerated by fresh produce.[22] Low dosage treatments (less than 1000 gray) enables trade across quarantine boundaries[23] and may also help reduce spoilage.

Impact[edit]

Irradiation reduces the risk of infection and spoilage, does not make food radioactive, and the food is shown to be safe, but it does cause chemical reactions that alter the food and therefore alters the chemical makeup, nutritional content, and the sensory qualities of the food.[24] Some of the potential secondary impacts of irradiation are hypothetical, while others are demonstrated. These effects include cumulative impacts to pathogens, people, and the environment due to the reduction of food quality, the transportation and storage of radioactive goods, and destruction of pathogens, changes in the way we relate to food and how irradiation changes the food production and shipping industries.

Immediate effects[edit]

The radiation source supplies energetic particles or waves. As these waves/particles pass through a target material they collide with other particles. Around the sites of these collisions chemical bonds are broken, creating short lived radicals (e.g. the hydroxyl radical, the hydrogen atom and solvated electrons). These radicals cause further chemical changes by bonding with and or stripping particles from nearby molecules. When collisions damage DNA or RNA, effective reproduction becomes unlikely, also when collisions occur in cells, cell division is often suppressed.[1]

Irradiation (within the accepted energy limits, as 10 MeV for electrons, 5 MeV for X-rays [US 7.5 MeV] and gamma rays from Cobalt-60) can not make food radioactive, but it does produce radiolytic products, and free radicals in the food. A few of these products are unique, but not considered dangerous.[25]

Irradiation can also alter the nutritional content and flavor of foods, much like cooking.[25] The scale of these chemical changes is not unique. Cooking, smoking, salting, and other less novel techniques, cause the food to be altered so drastically that its original nature is almost unrecognizable, and must be called by a different name. Storage of food also causes dramatic chemical changes, ones that eventually lead to deterioration and spoilage.[26]

Misconceptions[edit]

A major concern is that irradiation might cause chemical changes that are harmful to the consumer. Several national expert groups and two international expert groups evaluated the available data and concluded that any food at any dose is wholesome and safe to consume as long as it remains palatable and maintains its technical properties (e.g. feel, texture, or color).[10][11]

Irradiated food does not become radioactive, just as an object exposed to light does not start producing light. Radioactivity is the ability of a substance to emit high energy particles. When particles hit the target materials they may free other highly energetic particles. This ends shortly after the end of the exposure, much like objects stop reflecting light when the source is turned off and warm objects emit heat until they cool down but do not continue to produce their own heat. To modify a material so that it keeps emitting radiation (induce radiation) the atomic cores (nucleus) of the atoms in the target material must be modified.