User:GregGritton/LZB Draft

Linienzugbeeinflussung (or LZB) is a cab signalling and train protection system used on selected German and Austrian railway lines as well as the AVE in Spain. In Germany, the system is mandatory on all lines where trains exceed speeds of 160 km/h (200 km/h in Spain), but it is also used on some slower lines to increase capacity. The German Linienzugbeeinflussung translates to continuous train control, literally: linear train influencing. It is also called linienförmige Zugbeeinflussung.

Overview[edit]

In Germany, the standard distance from a distant signal to its home signal is 1,000 m. On a train with strong brakes, this is the braking distance from 160 km/h. In the 1960's Germany evaluated various options to increase speeds, including increasing the distance between distant and home signals, adding additional aspects, and cab signalling. Increasing the distance between the home and distant signals would decrease capacity. Adding an additional aspect would make the signals harder to recognize. In either case, changes to the conventional signals wouldn't solve the problem of the difficulty of seeing and reacting to the signals at higher speeds. To overcome all of these problems, Germany chose to develop continuous cab signalling.

The LZB cab signalling system was first demonstrated in 1965, enabling daily trains to the International Transport Exhibition in Munich to run at 200km/hr. The system was further developed through the 1970's, released on various lines in Germany in the early 1980's and in German, Spanish, and Austrian high-speed lines in the 1990's with trains running up to 300km/hr. Meanwhile, additional capabilities were added to the system.

LZB consists of equipment on the line as well as on the trains. A 30-40km segment of track is controlled by a LZB control center. [1] The control center computer receives information about occupied blocks from track cicruits or axle counters and locked routes from interlockings. It is programmed with the track configuration including the location of switches, graidents, and curve speed limits. With this, it has suffucient information to calculate how far each train may proceed and at what speed.

The control center communicates with the train using two conductor cables that run between the tracks and are crossed every 100 m. The control center sends data packets, known as telegrams, to the vehicle which give its movement authority (how far it can proceed and at what speed) and the vehicle sends back data packets indicating its configuration, braking capabilities, speed, and position.

The triain's on-board computer processes the packets and displays the following information to the driver:

- Current speed: locally derived from speed sensing equipment - shown with a standard speedometer

- Permitted speed: maximum allowed speed now - shown with a red line or triange on the outside of the speedometer

- Target speed: maximum speed at a certain distance - shown with LED numbers at the bottom of the speedometer

- Target distance: distance for target speed - shown with LED bars showing up to 4000m, with numbers for longer distances

If there is a long distance free in front of the train the driver will see the target speed and permitted speed equal to the maximum line speed, with the distance showing the maximum distance, between 4km and 13.2km depending on the unit, train, and line.

As the train approaches a speed restriction, such as one for a curve or turnout, LZB will sound a buzzer and display the distance to and speed of the restriction. As the train continues the target distance will decrease. As the train nears the speed restriction the permitted speed will start to decrease, ending up at the target speed at the restriction. At that point the display will change to the next target.

The LZB system treats a red signal or the beginning of a block containing a train as a speed restriction of 0 speed. The driver will see the same sequence as approaching a speed restriction except the target speed is 0.

LZB includes Automatic Train Protection. If the driver exceeds the permitted speed plus a margin LZB will activate the buzzer and an overspeed light. If the driver fails to slow the train the LZB system can apply the brakes itself, bringing the train to a halt if necessary.

LZB also include an Automatic Train Operation system known as AFB (Automatische Fahr- und Bremssteuerung, automatic driving and braking control), which enables the driver to let the computer drive the train on auto-pilot, automatically driving at the maximum speed currently allowed by the LZB. In this mode, the driver only monitors the train and watches for unexpected obstacles on the tracks.

Finally, the LZB vehicle system includes the conventional Indusi (or PZB) train protection system for use on lines that aren't LZB equipped.

History[edit]

Choice of Cab Signalling[edit]

In the 1960s the German railways wanted to increase the speeds of some of their railway lines. One issue in doing so is signalling. German signals are placed too close to allow high-speed trains to stop between them, and signals may be difficult for train drivers to see at high speeds.

Germany uses distant signals placed 1,000m before the main signal. Trains with conventional brakes, decelerating at 0.76m/s2, can stop from 140km/hr in that distance. Trains with strong brakes, usually including electromagnetic track brakes, decelerating at 1m/s2 can stop from 160km/hr and are allowed to travel that speed. However, even with strong brakes and the same deceleration, a train traveling 200km/hr would require 1,543m to stop, exceeding the signalling distance. Furthermore, as energy dissapated at a given acceleration increases with speed, higher speeds may require lower decelerations to avoid overheating the brakes, further increasing the distance.

One possibility to increase speed would be to increase the distance between the main and distant signal. But, this would require longer blocks, which would decrease line capacity for slower trains. Another would be to introduce multiple aspect signalling. A train travelling 200km/hr would see a "slow to 160" signal in the first block, and then a stop signal in the 2nd block.

Introducing multi-aspec signalling would require substantial reworking for the existing lines, as additional distant signals would need to be added on long blocks and the signals reworked on shorter ones. In addition, it wouldn't solve the other problem with high-speed operation, the difficulty of seeing signals as a train rushes past, especially in marginal conditions such as rain, snow, or fog.

Cab signalling solves these problems. For existing lines it can be added on top of the existing signalling system with little, if any, modifications to the existing system. Bringing the signals inside the cab makes it easy for the driver to see them. On top of these, the LZB cab signalling system has other advantages:

- The driver is immediately aware of signalling changes.

- This allows a driver to stop slowing down if a signal at the end of a block improves. It also allows the control center to instantly signal stop in the case of dangerous conditions such as a derailment or avelanche.

- The driver can electronically "see" a long distance down the track, allowing hime or her to driver the train more smoothly.

- A train following a slower train can "see" the slower train well in advance, coasting or using regnenerative braking to slow and thereby saving energy.

- It can signal a variety of speeds. (Conventional German signals in the 1960's could only signal 40 or 60km/hr for turnouts. Modern conventional German signals can signal any 10km/hr increment, but LZB can signal even finer increments.)

- It allows the track to be divided up into a large number of small blocks if necessary to increase capacity.

- It enables a more capable Automatic Train Protection

- It enables the AFB Automatic Train Operation system.

Given all of these advantages, in the 1960's the German railways chose to go with LZB cab signalling instead of increasing the signal spacing or adding aspects.

Development[edit]

The first prototype system was developed by German Federal Railways in conjunction with Siemens and tested in 1963. It was installed in Class 103 locomotives and presented in 1965 with 200km/hr runs on trains to the International Exhibition in Munich. From this Siemens developed the LZB 100 system and introduced it on the Munich-Augsburg-Donawörth and Hanover-Celle-Uelzen lines, all in Class 103 locomotives.[2] The system was overlaid on the existing signal system. All trains would obey the standard signals, but LZB equipped trains could run faster than normal as long as the track was clear ahead for a suffucient distance. LZB 100 could display up to 5km in advance.

The original installations were all hard-wired logic. However, as the 1970's progressed SEL developed the computer based LZB L72 central controllers and equipped other lines with them.

By the late 1970's, with the development of microprocessors, the 2-out-of-3 computers could be applied to on-board equipment. Siemens and SEL jointly developed the LZB 80 on-board system and eqipped all locomotives and trains that travel over 160km/hr plus some heavy haul locomotives. By 1991, Germany replaced all LZB 100 equipment with LZB 80/L 72.[2] [1]

When Germany built its high-speed lines, beginning with the Fulda-Würzburg segment that started operation in 1987, it incorporated LZB into the lines. The lines were divided into blocks about 1.5 to 2.5km long, but instead of having a signal for every block, there are only fixed signals at switches and stations, with approximately 7km between them. If there was no train for the entire distance the entry signal would be green. If the first block was occupied it would be red as usual. Otherwise, if the first block was free and a LZB train approached the signal would be dark and the train would proceed on LZB indications alone.

The system has spread to other countries. The Spanish equipped their first high-speed line, operating at 300km/hr, with LZB. It opened in 1992 and connects Madrid, Cordoba, and Seville. In 1987 the Austrian railways decided to introduce LZB, and with the 23 May 1993 timetable change introduced Euro City trains running 200km/hr on a 25km long section of the Westbahn between Linz and Wels.

Siemens continued to develop the system, introducing "Computer Inegrated Railroading", or "CIR ELKE", lineside equipment in 1999. This permitted shorter blocks and allowed speed restrictions for switches to start at the switch instead of at a block boundary. See CIR ELKE below for details.

Development timeline[edit]

| Date | Description | Control centers / Length |

|---|---|---|

| 1963 | Testing on Forchheim–Bamberg line | |

| 1965 | 200km/h presentation trips on the München–Augsburg line installed in Class 103 locomotives[3] | |

| 1974–1976 | Operations testing on the Bremen–Hamburg line | 3 controllers / 90 km |

| 1976 | Expanded the trial to the Hamm–Gütersloh line. | |

| 1978–1980 | S-Bahn pilot project in Madrid (RENFE) | 1 controller / 28 km |

| 1980–1985 | Operations start on some Deutschen Bundesbahn (DB) lines | 7 controllers / 309 km |

| 1987 | Operations start on new high-speed lines Fulda–Würzburg and Mannheim–Hockenheim | 4 controllers / 125 km |

| 1987 | Austrian Federal Railways decides to introduce LZB | |

| 1988–1990 | Further expansion to new routes in Germany | 2 controllers / 190 km |

| 1991 | Commissioning of the remainder of the Hanover–Würzburg high-speed railway, the Mannheim–Stuttgart high-speed railway and additional routes | 10 controllers / 488 km |

| 1992 | Opening of the Madrid-Sevilla high-speed rail line in Spain | 8 controllers / 480 km |

| 1992 | First section Wien–Salzburg route in Austria | 1 controller / 30 km |

| 1995 | Commissioning of the Madrid C5 Cercanias (suburban rail) line | 2 controllers / 45 km |

| 1998 | Commissioning of the Hanover–Berlin high-speed railway and expansion of the Nuremberg-Wurzburg route, paired with electronic interlockings. | 6 controllers |

| 1999 | Commissioning of the CIR ELKE pilot project on the Offenburg–Basel line, with CE1 system software | 4 controllers |

| 2001 | Commissioning of the CIR ELKE pilot project at Achern | 1 controller |

| 2002 | Commissioning of the Cologne–Frankfurt_high-speed_rail_line using CE2 system software | 4 controllers |

| 2003 | Commissionong of the upgrades to the Cologne–Düren(–Aachen) rail line (LZB with CE2-Software) | 1 controller / 40 km |

| 2004 | Commissionong of the upgrades to the Hamburg–Berlin rail line (LZB with CE2 system software) | 5 controllers |

| 2004 | Commissioning on the upgrades to the Munich S-Bahn using (CE2 software and shorter blocks) | 1 controller |

| 2006 | Commissioning on the upgrades to the Berlin–Halle/Leipzig line where LZB (CE2) and ETCS are combined for the first time. | 4 controllers |

| 2006 | Commissioning of the Nuremberg–Munich_high-speed_railway (LZB with CE2 system software with turnout extension) | 2 controllers |

Line equipment[edit]

Cable loops[edit]

The LZB control center communicates with the train using conductor cable loops. Loops can be as short as 50 meters long, as used at the entrance and exit to LZB controlled track, or as long as 12.7 km. Where the loops are longer than 100m they are crossed every 100m. At the crossing the signal phase angle is changed by 180° reducinng electrical interference between the track and the train as well as long-distance radiation of the signal. The train detects this crossing and uses it to help determine its position. Longer loops are generally fed from the middle rather than an end.

One disadvantage of very long loops is that any break in the cable will disable LZB transmission for the entire section, up to 12.7km. Thus, newer LZB installations, including all high-speed lines, brake the cable loops into 300m physical cables. Each cable is fed from a repeater, and all of the cables in a section will transmit the same information.

LZB route center (central controller)[edit]

The core of the LZB route center, or central controller, consists of a 2-of-3 computer system with two computers connected to the outputs and an extra for standby. Each computer has its own power supply and is in its own frame.[2] All 3 computers receive and process inputs and interchange their outupts and important intermediate results. If one disagrees it is disabled and the standby computer takes its place.

The computers are programmed with the fixed information from the route such as speed limits, gradients, and the location of block boundaries, switches, and signals. They are linked by LAN or cables to the interlocking system from which they receive indications of switch positions, signal indications, and track curcuit or axle counter occupancy. Finally, the route center's computers communicates with controlled trains via. the cable loops previously described.

Other equipment[edit]

- Repeaters: Repeaters connect individual 300m long loop sections to the primary communication links, strengthening the signal from the route senter and sending the vehicle responses.

- Fixed loops: Fixed loops, typically about 50m long, are placed at the ends of the controlled section. They transmit fixed telegrams which allow entering trains to receive and address.

- Isolation cabinets: A long communication link will consist of multiple individual cables connected in "isolation cabinets" which serve to prevent the low-frequency voltage which is coupled from the catenary from accumulating on the cable.

- Signs: Signs indicate the LZB block boundaries (if not at a signal) and the entrance and exit from the LZB controlled area.

Vehicle equipment[edit]

The vehicle equipment in the original LZ B80 designed consisted of:[2]

- Computers: The on-board equipment centered around a 2-of-3 computer system. The original LZB 80 design used 8085 microprocessors programmed in assembly language. The programs were interrupts driven, with initerrupts generated by a 70ms clock, the track receivers and transmitters, the serial interface, and also within the program itself. Interrupts triggered comparison and output programs. Peripheral equipment was arranged around the computers with all interfaces electrically seperated and all grounds tied to the cabinet frame which was tied to the vehicle chassis.

- Redundant power supply: The computers and peripherial equipment were supplied witha redundant power supply based on two identical voltage transformers. Each was capable of supplying the the power necessary for all of the quipment. They were normally alternately switched, but if one failed the other would take over. On-board batteries could also supply temporary power.

- Odomotry: The vehicle speed and distance travelled is measured on two independent channels by two pulse generators mounted on different axles. Each is linked seperate microcontroller based unit used to correct any innacuracies. The central logic polls the two units as well as an accelometer compares the values and checks for plausibility.

- Receiver: Two pairs of receiving antennas are each fed to selective, self-regulating amplifiers whose output is fed to a demodulator and then a serial-parallel transformer. The received telegrams are then fed byte to byte to the central logic. The receivers also indicate transitions points and whether the signal is present.

- Transmitter: The 2 outputting computers feed serial-parallel transformers. They are compared after conversion, and transmission is only allowed if they are identical. Only one is actually transmitted, with the transmitter transmitting the two signals at 56kHz with the signals displaced by a 90º phase angle.

- Emergency brake connection: The computers are connected to the brake via a relay. A computer command or loss of current will release the air from the brake pipe applying the emergency brake.

- INDUSI horn connection: The horn signalling the driver is also connected by a relay.

- Serial interface: A serial interface is used to connect the rest of the components, including the driver inputs, display unit, logger, and the tuomatic drive and brake control (AFB) to the computers. Telegrams are transmitted cyclically both from and to the computers.

- Driver input unit: The driver inputs train related data such as the type of braking (passenger/freight), braking potential, maximum train speed, and train length on the driver interface unit. This is then displayed to the driver to verify that it is correct.

- Modular cab display (MFA): The modular cab display shows the relevant speeds and distances to the driver as described in the overview.

- Automatic drive/brake control: When enabled by the driver, the automatic drive/brake control unit (AFB) will drive the train following the permitted speed. When not operating on an LZB equipped line, i.e. under INDUSI operation, the AFB acts as a "cruise control", driving according to the speed set by the driver.

The equipment in newer trains is similar, although the details may vary. For example, some vehicles use radar rather than accelerometers to aid in their odometry. The number of antennas may vary by vehicle. Finally, some newer vehicles use a full-screen computer generated "Man-machine interface" (MMI) display rather than the seperate dials of the "Modular cab display" (MFA).

Operation[edit]

Telegrams[edit]

LZB operates by exchanging telegrams between the central controller and the trains. The central coontroller transmits a "call telegram" using Frequency-shift keying (FSK) signalling at 1,200 bits per second on a 36kHz ± 0.4kHz. The train replys with a "response telegram" at 600 bits per second at 56kHz ± 0.2kHz. [4]

Call telegram format[edit]

Call telegrams are 83.5 bits long:

- Start sequence: Synchronization: 5.5 bits, Start element + baker code: 3 bits

- Address: Section ID: A-E, A1-A3, Location: 1-127 or 255-128

- Vehicle information: Travel direction: up/down, Braking type: passenger/freight, Brake curve number: 1-10, A-B

- Braking information: Distance to brake application: 0-1550m

- Nominal distance XG: 0-12775m, Target information, Distance: 0-12700m, Speed: 0-315km/hr

- Display information, Signal information: 3 bits, Additional information: 5 bits

- Auxiliary information: Group identity: 1-4 - Indicates response type requred, Line identity: new high-speed/normal main lines, Central controller type: LZB 100/72

- Cyclic redundancy check (CRC): 8 bits

One might note that there is no "train identification" field in the telegram. Instead, a train is identified by position. See Zones and Addressing for more details.

Reponse telegram format[edit]

There are 4 types of response telegrams, each 41 bits long. The exact type of telegram a train sends depends on the "Group identity" in the call telegram.

The most common type of telegram is type 1, which is used to signal a trains position and speed to the central controller. It contins the following fields: {LZB p3}

- Synchronization and start sequence: 6 bits

- Group identity: 1-4 - Indicates response type

- Vehicle location acknowledgement: number of zones advanced - ±0, ±1, ±2

- Location within zone: 0 - 87.5m (in 12.5m increments)

- Braking type: passenger/freight

- Brake curve number: 16 possible brake curves

- Actual speed: 0-315km/hr

- Operational and disgnostic information: 5 bits

- Cyclic redundancy check (CRC): 7 bits

The other telegrams are used primarily when a train enters the LZB controlled section. They all start with the same synchronization and start sequence and a "group identity" to identify the telegram type, and end with the CRC. Their data fields vary as follows:

- Type 2: Vehicle location acknowledgement, location within zone, braking type, brake curve number, maximum train speed, train length

- Type 3: Railway, train number

- Type 4: Locomotive/train series, serial number, train length

Entry into LZB, Zones and Addressing[edit]

Before entiner a LZB controlled section the driver must enable the train by entering the required information on the Driver Input Unit and enabling LZB. When enabled the train will light a "B" light.

A controlled section of track is divided into up to 127 zones, each 100m long. The zones are consecutively numbered, counting up from 1 in one direction and down from 255 in the opposite.

When a train enters a LZB controlled section of track, it will normally pass over a fixed loop that transmits a "change of section identification" (BKW) telegram. This telegram indicates to the train the section identification number as well as the starting zone, either 1 or 255. The train sends back an acknowledgement telegram. At that time the LZB indications are switched on, including the "Ü" light to indicate that LZB is running.

From that point on the train's location is used to identify a train. When a train enters a new zone it sends a response telegram with the "vehicle location acknowledgement" filed indicating that it has andvanced into a new zone. The central controller will then use the new zone when addressing the train in the future. Thus a trains address will gradually increase or decrease, depending on its direction, as it travels along the track. A train identifies that it has entered a new zone by either detecting the cable transpotition point in the cable or when it has travelled 100 meters.[2] A train can miss detecting up to 3 transposition points and still remain under LZB control.

The procedure for entering LZB controlled track is repeated when a train transitions from one controlled section to another. The train receives a new "change of section identification" telegram and gets a new address.

Until the train knows its address it will ignore any telegrams received. Thus, if a train doesn't properly enter into the controlled section it won't be under LZB control until the next section.

Speed signalling[edit]

The main task of LZB is signalling to the train the speed and distance it is allowed to travel. It does this by transmitting periodic call telegrams to each train one to five times per second, depdending on the number of trains present. Four fields in the call telegram are particularly relevant:

- Target distance

- Target speed

- Nominal stopping distance, known as "XG" (See below)

- Distance to brake application poin

The target speed and location are used to display the target speed and distance to the driver. The train's permitted speed is calculated using the trains braking curve, which can vary by train type, and the XG location, which is the distance from the start of the 100m zone that is used to address the train. If the train is approaching a red signal or the beginning of an occupied block the location will match the location of the signal or block boundary. The on-board equipment will calculate the permitted speed at any point so that the train, decelerating at the deceleration indicated by its braking curve, will stop by the stopping point.

A train will have a parabolic braking curve as follows:

where:

- decel = deceleration

- dist = distance from beginning of 100m zone

Where a train is approaching a speed restriction the control center will transmit a packet with an XG location set to a point behind the speed restriction such that a train, decelerating based on its braking curve, will arrive at the correct speed at the start of the speed restriction. This, as well as deceleration to zero speed, is illustraded with the green line in the "Permitted and supervised speed calculation" figure.

The red line in the figure shows the "monitoring speed", which is the speed which, if exceeded, the train will automatically apply the emergency brakes. When running at constant speed this is 8.75km/hr above the permitted speed for transitend emergency braking (until speed is reduced) or 13.75km/hr above the permitted speed for continuous emergency braking. When approaching a stopping point, the monitoring speed follows a braking curve similar to the permitted speed, but with a higher deceleration, that will bring it to zero at the stopping point. When approaching a speed restriction, the monitoring speed braking curve intersects the speed restriction point at 8.75km/hr above the constant speed.

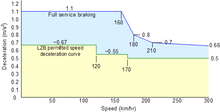

Deceleration rates are more conservative with LZB than with conventional German signalling. A typical passenger train braking curve might have a "permitted speed" deceleration of 0.5m/s2 and a "monitoring speed" deceleration of 0.71m/s2, 42% higher than the deceleration for the permitted speed, but lower than the 0.76m/s2 required to stop from 140km/hr in 1,000m. The ICE3, which has a full service braking deceleration of 1.1m/s2 below 160km/hr, dropping to 0.65km/hr by 300km/hr, has a LZB target speed deceleration of only 0.68m/s2 to 120km/hr, 0.55m/s2 between 120km/hr and 170km/hr, and 0.5m/s2 at higher speeds.[5]

In between the permitted speed and monitoring speed is a warning speed, normally 5km/hr above the permitted speed. If the train exceeds that speed LZB will flash the "G" light on the train's display and sound a horn.

Leaving LZB[edit]

About 1700m before the end of the LZB controlled section the central controller will send a telegraam to announce the end of LZB control. The train will flash the "ENDE" light which the driver must acknowledge within 10 seconds. The display will normally give the distance and target speed at the end of the controlled section, which will depend on the signal at that point.

When the train reaches the end of LZB control the "Ü" and "ENDE" lights go off and the conventional INDUSI (or PZB) system takes over automatic train protection.

Special operating modes[edit]

Special conditions not covered by the full LZB system or failures can put LZB into one of the special operating modes.

Crossover to opposite track[edit]

As a train approaches a crossover to a normally opposite direction track the display will flash the "E/40" light. The driver confirms the indication and the permitted speed drops following the braking curve to 40km/hr. When the crossover section is reached the displays are switched off and the driver can proceed through the crossover at 40km/hr.

Drive by sight signal[edit]

German signalling systems have a "drive by sight" signal that consists of 3 white lights forming a triangle with one light at the top. This signal, labeled "Zs 101", is placed with a fixed line side signal and, when lighted, permits the driver to pass a fixed red or defective signal and drive by sight to the end of the interlocking no faster than 40km/hr.

When approaching such a signal in LZB territory the "E/40" light will be lit until 250m before the signal, then it will "E/40" will go dark and "V40" will flash. The "V40" signal indicates the ability to drive by sight.

Transmission Failure[edit]

If data exchange is interrupted, the trains distance measurement system fails, or the train fails to detect 4 or more cable transposition points the LZB system will go into a failure state. It will light the "Stör" indicator and then falsh "Ü". The driver must acknowledge the indications within 10 seconds. The driver must slow the train to no more than 85km/hr or lower; the exact speed depends on the backup signalling system in place.

Extensions[edit]

CIR ELKE[edit]

CIR-ELKE (Computer Integrated Railroading - Increasing the Effeciency in the Core Railway Network) is an improvement on the basic LZB system. It uses the same physical interface and packets as standard LZB but upgrades its software, adding capabilities and modifying some procedures. It it designed to increase line capacity by up to 40% and to further shorten travel times.

CIR-ELKE includes the following improvements:

- Shorter blocks - CIR-ELKE blocks can be as short as 300 meters, or even shorter for S-Bahn systems. The Munich S-Bahn system has blocks as short as 50 meters at the beginning of the platform, allowing a train to pull into the platform as another is leaving and making it capable of runnings 30 trains per hour.

- Speed changes at any location - The standard LZB system required that speed restrictions start at block boundaries. With CIR-ELKE speed restrictions can start at any point, such as at a turnout. This means a train doesn't have to slow down as soon, increasing average speeds.

- Telegram evaluation changes - In order to increase safety on a system with shorter intervals between trains CIR-ELKE sends identical telegrams twice. The train will only act on a telegram if it receives two idential valid telegrams. In order to compensate for the increase in the number of telegrams CIR-ELKE sends talegrams to non-moving trains less frequently.

CIR ELKE-II[edit]

The original LZB sysem was designed for permitted speeds up to 280 km/hr and gradients up to 1.25%. The Cologne-Frankfurt high-seed line was designed for 300 km/hr operation and has 4% gradients; thus, it needed a new version of LZB, and CIR ELKE-II was developed for this line.

CIR ELKE-II has the following features:

- Maximum speed of 300km/hr.

- Support for braking curves with higher decelerations and curves taking into account the actual altitude profile of the distance ahead instead of assuming the maximum downslope of the section. This makes operation on 4% gradients practical.

- Support for target distances of up to 35,000m to a stopping or speed restriction point. If there is no such point within that distance the system will display a target distance of 13,000m and a target speed of the line speed.

- Signalling voltage or phase changes.

- Audiable warning signals 8 seconds before the point of braking, or 4 seconds for the Munich S-Bahn, instead of 1000m before or with a 30km/hr speed difference done previously.

Malfunctions[edit]

The LZB system has been quite safe and reliable; so much so that there have been no collisions on LZB equipped lines bacause of the failure of the LZB system. However, there have been some malfunctions that could have potentially resulted in accidents. They are:

- On June 29, 1991, after a disturbance, the train driver had the LZB system off and passed a stop signal with 2 trains in the tunnel at Jühnde on the Hanover-Würzburg high-speed line.

- On June 29, 2001, there was nearly a serious accident at the Oschatz crossover on the Leipzig-Dresden railway line. The crossover was set to diverging with a 100km/hr speed limit but the LZB system displayed a 180km/hr limit. The driver of ICE 1652 saw the diverging signal and slowed to 170km/hr before the crossing and the train didn't dereail. A software error in the LZB computer was suspected as the cause.

- A similar near-accident occured on November 17, 2001 in Bienenbüttel on the Hamburg-Hannover rail line. In order to pass a freight train an ICE train crossed over to the opposite track going 185km/hr through a crossover that was rated at 80km/hr. The suspected cause was faulty execution of a change to the interlocking circuits, where the crossover speed was increased from 60km/hr to 80km/hr. The faulty circuits allowed the LZB system to display the 200km/hr line speed instead of the 80km/hr speed required for the crossing.

- On April 9, 2002 on the Hanover-Berlin hgih-speed line a fault in the LZB line center computer brought two LZB controlled trains in each line direction to a stop. When the computer was rebooted it signalled 0km/hr to the trains in front and 160km/hr to the following trains. One of the following train drivers saw the train in front of him, and the other double-checked with the operations center which warned him prior to departure, so two possible accidents were averted.

Routes[edit]

Equipped lines[edit]

DB (Germany)[edit]

The following lines of Deutsche Bahn are equipped with LZB, allowing for speeds in excess of 160 km/h (providing the general suitability of the track):

- Augsburg - Dinkelscherben - Ulm (km 7,3 km 28,5)

- Berlin - Nauen - Glöwen - Wittenberge - Hagenow Land - Rothenburgsort - Hamburg (km 16,5 - km 273,1)

- Bremen - Hamburg (km 253,9 - km 320,1)

- Dortmund - Hamm (Westf) - Bielefeld (except for the station of Hamm)

- Frankfurt am Main - Gelnhausen - Fulda (km 24,8 - km 40,3)

- Hannover - Stadthagen - Minden (km 4,4 - km 53,4)

- Hannover - Celle - Uelzen - Lüneburg - Hamburg (km 4,0 - km 166,5)

- Hannover - Göttingen - Kassel-Wilhelmshöhe - Fulda - Würzburg (km 4,2 - km 325,6)

- Karlsruhe - Achern - Offenburg - Kenzingen - Leutersberg - Weil am Rhein - Basel Bad. Bf. (km 102,2 - km 270,6)

- Köln - Aachen (km 1,9 - km 41,8)

- Köln - Düsseldorf - Duisburg (km 6,7 - km 37,3 and km 40,1 - km 62,2; Düsseldorf main station is not equipped)

- Köln - Troisdorf - Montabaur - Limburg a.d. Lahn - Frankfurt am Main (km 8,7 - km 172,6)

- Leipzig - Wurzen - Dresden (km 3,6 - km 59,5)

- Lengerich (Westf) - Münster (Westf)

- Lehrte - Stendal - Berlin-Spandau

- Mannheim - Karlsruhe

- Mannheim - Vaihingen an der Enz - Stuttgart (km 2,1 - km 99,5)

- München - Augsburg - Donauwörth (km 9,2 - km 56,3 and km 2,7 - km 39,8; Augsburg main station is not equipped)

- Nürnberg - Allersberg - Kinding - Ingolstadt-Nord (ABS: km 97,9 - km 91,6; NBS: km 9,0 - km 88,7)

- Nürnberg - Neustadt an der Aisch - Würzburg (km 34,8 - km 62,7)

- Osnabrück - Bremen (km 139,7 - km 232,0)

- Paderborn - Lippstadt - Soest - Hamm (Westf) (Strecke 1760: km 125,2 - km 180,8; Strecke 2930: km 111,5 - km 135,6)

- Zeppelinheim bei Frankfurt/Main - Mannheim

Note: italics indicate the physical location of an LZB control center.

ÖBB (Austria)[edit]

- Wien - Pöchlarn - St. Valentin - Wels - Salzburg (km 62,4 - km 108,6; km 125,9 - km 165,0; km 190,5 - km 241,6)

RENFE (Spain)[edit]

- Madrid - Córdoba - Sevilla (9 Zentralen / 480 km), operational since 1992. Since 2004, the terminus MadridAtocha is also equipped with LZB. In November 2005, a branch line to Toledo was opened. (20 km).

- Cercanías Madrid line C5 from Humanes over Atocha to Móstoles-El Soto. It is 45km long with 2 LZB centres and 76 Series 446 vehicles.

- All EuskotrenBideak network with the exception of the Euskotran network.

Non-Mainline Uses[edit]

In addition to mainline railways, versions of the LZB system are also used in suburban (S-Bahn) railways and subways.

Dusseldorf, Duisburg, Krefeld, Mülheim an der Ruhr[edit]

Tunnels in the Dusseldorf and Duisburg U-bahn (subway) system, and some of the tunnels in the Mülheim an der Ruhr U-bahn are LZB equipped.

Vienna (Wien)[edit]

With the exception of line 6, the entire Vienna U-Bahn is equipped with LZB since it was built and includes the capability of automatic driving with the operator monitoring the train.

Munich[edit]

As with Vienna, the Munich U-Bahn was built with LZB control. During the regular daytime the trains are automatically driven with the operator simply starting the train. Stationary signals remain dark during that time.

In the evenings from 9:00PM and on Sundays the operators drive the trains manually according to the stationary signals in order to remain in practice.

There are plans to automate the placement and reversal of emptry trains.

Nuremberg[edit]

The Nuremberg U-Bahn U3 line uses LZB for fully automatic (driverless) operation. The system was jointly developed by Siemens and VAG Nuremberg and is the first system where driverless trains and conventional trains share a section of line. The existing, conventionally driven U2 line trains shares a segment with the automatic U3 line trains. Currently, an employee still accompanies the automatically driven trains, but later the trains will travel unaccompanied.

After several years of delays, the final three-month test run was successfully completed on April 20, 2008, and the operating licence granted on April 30, 2008. A few days later the driverless trains started operating with passengers, first on Sundays and public holidays, then weekdays at peak housrs, and fially after the morning rush hour which has a tight sequence of U2 trains. The official opening ceremony for the U3 line was held on June 14, 2008 in the presence of the Bavarian Prime Minister and Federal Minister of Transport, the regular operation began with the schedule change on 15 June 2008. The Nuremberg U-bahn plans to convert U2 to automatic operation in about a year.

London[edit]

The Docklands Light Railway in east London uses the SELTRAC technology which was derived from LZB to run automated trains. The trains are accompanied by an employee who closes the doors and signals the train to start, but then is mainly dedicated to customer service and ticket control. In case of failure the train can be driven by hand from a stand. Originally 22km of double track to serve the Canary Wharf financial district, the system has been expanded to include the Lewisham extention, The London City Airport extention and most recently the Stratford Airport extention. Other SELTRAC systems include: SRT (Scarborough Rapid Transit) line in Scarborough, Ontario, Canada; DPM (Detroit People Mover) Detroit, Michigan, USA; Vancouver Sky Train and Canada Line, Vancouver, BC, Canada; JFK (John F. Kennedy) Airport, New York, USA; MUNI (Municipal Railway), San Francisco, California, USA; Wuhan LRT, Wuhan, PRC (Peoples Republic of China); KCRC-WR (Kowloon-Canton Railway Corporation - West Rail) & MOS (Ma On Shan), Hong Kong, PRC; Guangzhou Metro Line 3, Guangzhou (Canton), PRC; Dubai Metro, UAE (United Arab Emirates); Kuala Lumpur LRT2, Kuala Lumpur, Malasia; Ankara, Turkey; Al Mashaaer Al Mugaddassah Metro (Mecca Metro), Makkah, Saudi Arabia; SBL (Sin Bundang Line), Seoul, South Korea.

European Train Control System[edit]

Different European countries currently have a variety of train signalling systems. In order to standarize operations and allow a train to pass through Europe without switching locomotives or needing to be equipped with many signalling systems Europe has developed the European Train Control System (ETCS). The European Union has required that European nations adopt ETCS which is currently in its initial implementation phases. It is supposed to eventually replace all national systems.

LZB is considered a "Class B" system within ETCS. A train can be equipped with a LZB "Specific Transmission Module" (STM) which allows ETCS on-board equipment to communicate with LZB ground equipment. In addition, lines can be dual-equipped with both ETCS and LZB, allowing trains equipped with either system to traverse the line at full speed. The line from Jüterbog to Halle/Leipzig is dual-equipped.

References[edit]

- ^ a b Signalling System for German High Speed Lines, by H. Uebel, Standard Elektrik Lorenz A.G., Stuttgart, Germany, presented in the "1989 International Conference on Main Line Railway Electrification", p 36-39.

- ^ a b c d e Continuous Automatic Train Control and Cab Signalling with the LZB 80, by H. Sporleder, Siemens, AG, published in the "1989 International Conferende on Main Line Railway Electrification", p 40-46.

- ^ Der ICE – ein Produkt des Systemverbundes Bahn. In: Deutsche Bahn AG: (http://www.db.de/site/shared/de/dateianhaenge/publikationen__broschueren/bahntech/bahntech200601.pdf) bahntech, Nr. 1/06], S. 24 f.

- ^ Directive 96/48/EC, Interoperability of the trans-European high speed rail system, Draft Technical Specification for Interoperability, Part 3, annexes to the TSI, "Control-Command and Signalling" Sub-System, 19.05.2006.

- ^ "The Linear Eddy-Current Brake of the ICE 3" by Dr.-Ing. Wolf-Dieter Meler-Credner and Dipl.-Ing. Johannes Gräber, published in Railway Technical Review (RTR), April, 2003